JSW Steel Limited – Dolvi

JSW Steel Ltd is an Indian multinational steel producer. For their steel plant located at Dolvi near Mumbai JSW was using mobile harbour crane to handle cargo and was facing issue with reliability and high operation cost.

The operation was to unload from barges and feed it on to hoppers of above 10 meter height. Sennebogen offered 2 units of 880EQ crawler machine with 7 meter pylon, 430 kW electric motor, boomstick with 30 meter outreach, 6cbm clamshell grab for iron ore, limestone, pellets and dolomite handling and 14cmb clamshell grab for handling coal.

The two Sennebogen machines were chosen for their simplicity in maintenance & ability to operate non-stop in hot & dusty condition with fast cycle time for cargo handling. The machines are in operation for approximately 20 hours per day & the JSW machine operators had no difficulties in adjusting to the new machines.

The JSW management decided to opt for electric motor engine rather than diesel motor engine which resulted in reduction of Operation & Maintenance cost by more than 30 percent vis-à-vis its diesel engine model. The 880EQ has no complicated electronics and is a hydraulic material handling machine making it very operator friendly. The counterweights of the 880EQ are equally distributed so as to attain the center of gravity in such a way that the machine would have uniform load carrying capacity in complete 360 degrees. This means that only a small amount of energy is needed to drive the equipment – even when large operating ranges and heavy loads are involved.

Sennebogen 880EQ is in demand when there is a large work area to be covered and is ideally suited to the challenging work of unloading bulk cargo and general cargo from ships up to Handymax size.

These two giant units of Sennebogen are in operation since 2014.

Grasim Industries Limited

Grasim Industries Ltd is a flagship company of Aditya Birla Group. Customer had a requirement of continuous log feeding at their Chipper unit. Operation was being handled by two units of Excavators in each shift. Customer was facing low efficiency due to spillage & inefficient handling of logs. Also unreliability of operation due to frequent breakdown, high operation cost due to diesel run machine & a backup machine had to be kept ready for any breakdown.

We visited Grasim site located at Harihar, Karnataka and offered solution with Sennebogen model 818 Electric. Machine was offered on mobile undercarriage with diesel travel powerpack, 9 meter boomstick configuration and moveable cabin to ensure better operational area view by the operator. The machine works with 0.6 cbm log grab to feed the chipper unit hopper. Sennebogen machines are in operation for approximately 18 hours per day.

Sennebogen 818 electric model were commissioned at Harihar plant in 2017.

ACC Ltd

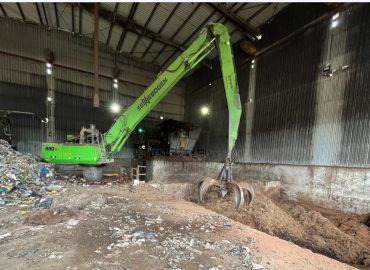

Geocycle India is a part of ACC Ltd, Holcim Group. Geocycle had a requirement for a very unique machine to work at their municipal waste processing at their Wadi, Karnataka plant. The machine was required to feed their two-shredding machine with 17-meter of outreach.

Sennebogen offered 830 electric model stationed on concrete foundation and remotely operated. It has a 16 meter boomstick configuration and works with orange peel grab of 2.5cbm size. Sennebogen 830 has a great number of potential configurations which makes it one of the most popular model.

Sennebogen 830 at Geocycle India is working for more than 13000 hours since 2019.

Adani Krishnapatnam Port Limited

Adani Krishnapatnam Port Company Limited located at Nellore District of Andhra Pradesh is one of the largest port on eastern cost of India.

Sennebogen 880EQ was chosen to handle bulk and break-bulk cargos like fertilizers, logs, scrap etc. The machine is fitted with a 470 kW diesel engine, 33 meter boomstick configuration and a broad-gauge crawler track undercarriage. It operates with 7cbm orange peel grab for scrap handling, 10cbm and 5cmb clamshell grab for heavy and light cargo respectively. The upper carriage sits on a 7 meter pylon and the forward position of the spacious and comfortable Port cab cabin offers the operator an ideal overview of the work area. The machine has been given a special anti-corrosion varnish for use in ocean environments. In addition customer found an efficient use of machine for dredging operation alongside the jetty. With an addition of extension at the end of stick the machine could reach 18 to 20 meters of depth at 35 meter radius.

The machine was commissioned in 2009.

Mukand Limited

Navyuga Engineering Company Ltd

Navayuga Engineering Pvt Ltd part of Navayuga Group is one of the well-known engineering and core infrastructure company. Navayuga had a special requirement for bridge construction project at Arunachal Pradesh for deep well sinking operation. Machine was required to dredge upto a depth of 14 meters with clamshell and orange peel grab.

Sennebogen offered 835 on crawler which is adaptable to any terrain for movement and boomstick configuration of 19 meters with 4 meter extension. The machine was also offered with 2 meter pylon for better visibility. Sennebogen 835 model combines proven high performance with low fuel consumption, maximum operating comfort and safety features for both the operator and the machine. After completion of bridge job the machines are currently working for break water construction at Vishakhapatnam.

Sennebogen supplied 4 units of 835R in 2010.

Harsco Metals Group Ltd

Harsco Metal Group Limited has a global footprint allowing them for safe, reliable delivery of products and services to multitude of companies.

For their new contract of drop ball operation at Dharamtar Port near Mumbai, Harsco was searching for efficient system that can offer higher balling rate as well as the reliability of the operation. Sennebogen material handlers are working with Harsco US unit and the same was suggested for the Harsco India Unit.

For the required operation of 10 ton ball from 12 meter height and to have lower operation cost Harsco selected Sennebogen 870 R electric machine with 18 meter boomstick configuration, in built 30 Kw generator for operation of dropball with magnet plate.

The machine is in operation at site since 2022.

Tamilnadu Newsprint and Papers Limited

Tamilnadu Newsprint and Paper Limited is one of the largest paper manufacturing company in India located near Karur, Tamil Nadu.

The company needed a reliable machine to operate 24 hrs per day at their chipper unit. Based on the operational condition and required feed rate and type of log at TNPL site, Sennebogen suggested Sennebogen 821 electric stationary machine with 11 meter boomstick configuration, 0.6 cbm log grab.

Customer is using 4 units of Sennebogen 821.

2 units were commissioned in 2009 at their Karur plant and

2 units were commissioned in 2021 at their Trichy plant

Shreeji Shipping Services India Ltd

Shreeji Shipping is a shipping service provider for handling bulk cargo.

Shreeji Shipping is using Sennebogen 835 Mobile diesel machine with banana boomstick configuration of 16 meters and 4 cbm clamshell grab for coal handling. These machines are in operation at Magdala port and Navlakhi Port.

Shreeji Shipping is using 2 units of 835 machine since 2021.

Esquire Shipping & Trading Pvt Ltd

Esquire Shipping & Trading Pvt Ltd is one of the leading shipping and trading company.

Esquire Shipping had a requirement for faster turnaround for Barges to handle of 2000 dwt.

Sennebogen offed them 880 classic on tyres configured with 20 meter boomstick, 570 kW diesel engine and 14 cbm clamshell grab.

Sennebogen 880 classic was commissioned at Roha Port, Maharashtra in 2014.

After Sennebogen 880’s impressive performance Esquire Shipping decided to go for one more unit of Sennebogen machine. Sennebogen 860 powered with 268 Kw engine, crawler undercarriage, 18 meter boomstick configuration and 6cbm clamshell grab for coal handling.

Second Machine was commissioned in 2016.

Shree Krishna Stevedores Pvt Ltd

Shree Krishna Stevedores Pvt Ltd is a logistic and service provider of bulk and bagged cargo handling.

Shree Krishna is using 2 units of Sennebogen 830 Mobile diesel machine with 17 meters boomstick configuration with 3 cbm clamshell grab and 1 unit of Sennebogen 835 Mobile diesel machine with 18 meters boomstick configuration for coal handling.

Shree Krishna is using the machine since 2014

.

Shree Krishna is using the machine since 2014.

Aarti Greentech Limited

Aarti Greentech Ltd was formed in partnership with TATA Recycling business to venture into scrap processing. As it was the first project of scrap processing the team were looking for the best to use for their first plant at Rohtak, Haryana.

The main operation was unloading scrap from truck, heaping and feeding operation. Sennebogen offered 821 Mobile diesel machine with 12 meter boomstick configuration, with in built 9kW generator for magnet plate operation and orange peel 0.6cbm grab.

Two units of Sennebogen 821 were commissioned in 2020.

VSV Enterprises

VSV Enterprises is a service provider for TATA Steel headquartered in Jamshedpur and provides services in Kalinganagar, Odisha and Jamshedpur.

RSGM Techno Services Pvt Ltd

RSGM Techno Services Pvt Ltd is a contractor for Jindal Stainless Ltd and provides various operation and service to industries at Odisha, Jajpur. Sennebogen material handler was suggested to RSGM team by Jindal Stainless Ltd.

Customer bought 1 unit of Sennebogen 825 mobile diesel machine with 13-meter boomstick configuration and 3 units of Sennebogen 821 mobile diesel machine with 11-meter boomstick configuration. Machine has in built magnet generator for magnet plate operation and also works with orange peel 0.6 cbm grab.

Customer is using the machines since 2019.

United Air Express.

United Air Express is one of the biggest contractors of Tata Steels and offers services of handling tertiary services and providing manpower.

Their requirement was for the machine which can be easily maintained and easy availability of spare parts. The operation was for loading of slag into truck with magnet.

Sennebogen offered Sennebogen 821 on crawler with diesel engine of 97 kW, inbuilt magnet system of 1350 mm Diameter and boomstick with 11 meter configuration.

The machine was commissioned in 2017 at Jamshedpur plant and is in operation for more the 13000 working hours.

United Infracore Limited (UIL)

United Infracore Limited (UIL) has its corporate office at Jamshedpur. UIL has the expertise in specialized jobs inside Steel & Cement Plants. With its strong pan India presence & association with all leading steel manufacturer of the country, UIL have received remarkable appreciation.

Sennebogen material handler was suggested by TATA Steels team. UIL bought Sennebogen 818 mobile diesel machine with 9-meter boomstick configuration with orange peel grab.

UIL is using Sennebogen machine since 2022.

Minaxi Handling Agency

Minaxi Handling Agency is based in Gandhidham, Gujarat. It provides port handling & transportation services associated with import and export of international as well as coastal goods in break bulk as well as containerized mode.

JSW Steel Ltd – Vijayanagar

JSW Steel Ltd – Vijayanagar is the sixth largest steel plant in the world. It is located in the Ballari-Hospete iron ore belt region in state of Karnataka and is well connected to both Goa and Chennai ports. With cutting edge technology and constant innovation, it has emerged as a steel plant with one of the most efficient conversion costs globally

Afcons Infrastructure Limited

Afcons Infrastructure Limited is an Indian multinational construction and engineering company based in Mumbai. Afcons is part of Shapoorji Pallonji Group which has a legacy of over 150 years. It is one of the India’s fastest growing infrastructure companies and has a portfolio of extremely challenging and complex projects worldwide.

One unit is working inside the yard for loading and unloading of jetty construction material (Tripod, Angles, beams, Slabs etc) from truck & trailer. Second unit is working at jetty to unload slabs and place in correct way to construct jetty.

Trafigura India Pvt Ltd

Trafigura India Private Limited, the first subsidiary of the Trafigura Group, was looking for multi-purpose machine for sorting of scrap, heaping, loading and unloading.

United Shippers Limited

United Shippers Limited is one of the well know company involved in shipping, logistics and its related activities.

Customer was looking for material handler with handling rate of 400 tph and above to handle 2000 tons barges at Navlakhi Port.

Sennebogen offered 835 Mobile diesel machine with banana boomstick configuration of 16 meters and 4 cbm clamshell grab for coal handling. Sennebogen machine is mainly used at jetty for coal unloading from the barges on to the dumper at the jetty.

The first unit was commissioned in 2017 and second unit was commissioned in 2019.

JM Baxi and Company

J M Baxi is India’s premier shipping service company in marine services, ports and logistics and technology.

Customer was looking to replace its existing operation of cargo handling with excavator to modern material handlers for its site in Haldia. Sennebogen offered 830M with 17meters boomstick configuration and 3cbm clamshell grab for coal handling and 1.5 cbm grab for iron ore handling.

Machine was commissioned in 2012.

Bangladesh Steel Re-Rolling Mills Ltd

Bangladesh Steel Re-Rolling Mills Ltd is one of the leading and largest steel manufacturing company in Bangladesh.

BSRM was using loaders and excavators for handling scrap. We convinced the customer to move from the traditional equipment to efficient system of scrap handling with material handlers. As the major operation was for handling scrap from trucks and heaping upto height of 12 meters. Sennebogen offered model 825 on crawler with 129Kw of Engine, boomstick configuration of 12 meter. Machine was supplied with magnet that is powered with 15kW in built generator and 0.6cbm orange peel grab.

Since its first purchase in 2012, BSRM has more than 8 units of Sennebogen machine working at their plant for more 30,000 hrs.